FootMILL® - CAD

Insole, Last & Bedding

- The processing of your 3D scanned copysocks, gypsum and foot foams, including further measurements, eg. footstep, foot scan or other images.

- The processing of the scanned model to a strip / insert including all necessary correction possibilities

- The processing of existing library last, inserts with individual sole plastic, for example from scraped foams

- Free modeling of any kind whether claws, lowering, pelots or other

- Transfer of the soles to the bedding construction / linings / last

- Transfer of the CAD data to all standard shaft programs

- Editing your 3D scanned or designed lasts.

- Import the roles from a personal library

Prosthetics

These CAD applications are all about orthopedic technology. For the field of orthopedic technology, we have created our FootMILL® - CAD - OT division. Orthopedic technicians make orthotics, AFO's, prostheses, helmets and corsets according to your requirements.

A new product from our company, which is constantly evolving.

Of course, the programs are also oriented towards the daily work of orthopedic technology which means no learning of new work flows. These programs are of course also open to import and export all current CAD file formats.

3D scanning

FootMILL® - CAD is open to all scanners, which can display their data in the format of: stl, vrml, wrl, obj, step, iges, dwg, dxf, asc, raw, 3ds, eps, 3dm or similar.

Choose your scanner according to your needs. Make sure that the data is output in a free format.

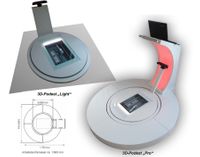

3D HandScanner - Professional:

The absolute all-connoisseur. Mobile, high-resolution and scans whatever it needs from the head to the feet. The supplied glasplate will allow you to scan your feet both plantar and everything else.

FootMILL® - CAM

Output your CAD data to a milling machine or a 3D printer. Whether purchased from us, or with your own.

In over 90% of all cases it is possible to use your existing machine park. Just ask us.

Milling control for 3-7 axes, according to your requirements

No matter whether you want to use the milling machine or use your machine park. The connection succeeds in over 90% of all cases, before you buy.

3D printing

Four different printer sizes, always the right choice for you.

All printers are suitable for continuous industrial use.